Revista Internacional de Ciencias Sociales, 43/2022

Social and environmental effects of mining in Southern Europe (pp. 101-114)

DOI: https://doi.org/10.6018/areas.505841

Phosphate mining in the mining basin of Extremadura, 1865-1956

Jesús Mª Martínez Milán

University of Las Palmas de Gran Canaria ULPGC

Abstract

Although the presence of phosphate in Cáceres (Spain) was known from the eighteenth century, it was not until the mid-nineteenth century, with the discovery of single superphosphate, that Extremadura became one of the principal exporting centres of phosphate in Europe. However, at the end of the century, new phosphate deposits began to be exploited in the United States and Africa, which relegated the phosphate from Cáceres to a secondary position. In this study, we analyse phosphate mining in Spain, examining the characteristics of its deposits and the evolution of the mining operations. Furthermore, we highlight the paradox that, despite having phosphate deposits, in the twentieth century Spain was a net importer of phosphate rock.

Keywords

Mining, Phosphate, Cáceres, Business, Production

JEL codes: L72, N57, N4, N8

LA MINERÍA DEL FOSFATO EN LA CUENCA MINERA DE EXTREMADURA, 1865-1956

Resumen

Aunque la presencia de fosfato en Cáceres (España) se conocía desde el siglo XVIII, no fue hasta mediados del siglo XIX, con el descubrimiento del superfosfato simple, cuando Extremadura se convirtió en uno de los principales centros exportadores de fosfato de Europa, hasta que a finales de la centuria se pusieron en marcha nuevos yacimientos de fosfato en Estados Unidos y África que relegaron al fosfato cacereño a un segundo plano. En este trabajo abordamos el estudio de la minería del fosfato en España, analizando las características de sus yacimientos y la evolución de las explotaciones mineras. En él destacamos la paradoja de que, a pesar de contar con yacimientos de fosfatos, España fue un país en el siglo XX netamente importador de mineral de roca fosfática.

Palabras clave

Minería, Fosfato, Cáceres, Empresa, Producción

Códigos JEL: L72, N57, N4, N8

Original reception date: December 26, 2021; final version: March 8, 2022.

Jesús Mª Martínez Milán, Departamento de CC. HH), Facultad de Economía, Empresa y Turismo (módulo E, despacho 111), University of Las Palmas de Gran Canaria, c/ Saulo Torón 4, 35017 – Las Palmas de Gran Canaria (Spain)

Tel.: +34 677112753; E-mail: jesus.martinez@ulpgc.es; ORCID ID: 0000-0002-1892-7491.

Phosphate mining in the mining basin of Extremadura, 1865-19561

Jesús Mª Martínez Milán

University of Las Palmas de Gran Canaria ULPGC

1. Introduction1

The discovery of phosphorite in Cáceres at the end of the eighteenth century, together with the emergence of single superphosphate as a chemical fertiliser in the following century, transformed Extremadura into one of the principal phosphate exporting centres of Europe at the end of the nineteenth century until the arrival of new competitors to the global phosphate rock relegated Spanish phosphate to a secondary position.

The literature on phosphate mining in Extremadura is scarce. Studies have been carried out on the mining heritage of Extremadura by Sánchez (2009) and Boixereu (2004 and 2014). Others have been conducted on the lawsuit regarding the ownership of the principal phosphate deposit of Logrosán, by Boixereu (2003) and Llanderas (2016). We can also highlight the analysis of the mining nuclei conducted by Gómez (1978) and Martínez and Boixereu (2021) who study the case of Aldea Moret, a phosphate mining village.

The objective of this article is to analyse the evolution of the mining activity of phosphorite in Cáceres from the beginning of operations until the closure of the mines in the 1850s. On this basis, the study is structured into four sections. The first addresses the evolution of phosphate mining during the mining boom, with the creation of British, Spanish and French companies. The second section studies the creation and development of the mining village of Aldea Moret. The third analyses the evolution of the production, export and consumption of phosphate in Spain, identifying two well-differentiated stages. The first stage consisted in the export of phosphate from Extremadura. The second, from the end of the nineteenth century to the closure of the mines in Cáceres, was characterised by decline, the national orientation of production and the increase in the imports of phosphate from the United States and the Maghreb. The final section examines the last attempts to maintain phosphate mining alive, with the construction of superphosphate factories in Cáceres and Badajoz and the increase in the processes of technification and labour organisation in the mines.

2. Origin and development of phosphate mining in Extremadura (1850-1895)

Since ancient times, there had been an awareness of a curious whitish mineral in Logrosán (Cáceres) which, after being crushed, produced blue phosphorescent sparks when thrown into the fire (Roso de Luna, 2007: 18). However, it was not until the second half of the eighteenth century that the British naturalist Bowles (1789) and the French chemist Proust (1791) presented the phosphorite from Logrosán to the world, the existence of which was already recorded in the Respuestas Generales del Catastro del Marqués de la Ensenada (1750-1754). Notwithstanding, the interest in the phosphate deposits, particularly those of Extremadura, did not acquire notoriety and importance until the mid-nineteenth century, with the onset of the agricultural revolution in north-west Europe and the registration of the patent of the British-born J. B. Lawes to manufacture the first phosphate chemical fertilizer (single superphosphate2). According to Boixereu (2014: 5), until then, the only use for phosphorite was the “manufacture of porcelains”.

In the geological and mining description of Cáceres, undertaken in 1876 by the mining engineers Egozcue and Mallada, phosphate was grouped into three different geological areas; first were the deposits with the mineral in granite form scattered across most of the province; second, the deposits cut with chalk, such as those of Calerizo de Cáceres (south of the capital) and finally, those that cut the Cambrian slates (Logrosán), where the largest seam was located (La Costanaza), due to the abundance and potential of the mineral (Egozcue and Mallada, 1876: 184). We will start with the latter.

In 1875, the American chemist Charles U. Shepard (Shepard, 1879) arrived to Logrosán, as part of a tour through Europe to study the principal phosphate deposits. This trip, funded by a North American entrepreneur and owner of phosphate mines in South Carolina, had the objective of analysing the possibilities that the phosphate from south-east America would have in the European market. After analysing samples collected from four countries (Norway, the United Kingdom; France and Spain), Shepard concluded that the only competitor that threatened the American phosphate was that of Logrosán. The four samples collected by this chemist in the seam of La Costanaza and Nuestra Señora del Consuelo had an average quality of 86.5% BPL3. The German chemist Niederstadt shared Shepard’s opinion. He believed that the phosphorite that Germany imported from Extremadura was superior to that obtained in the phosphate mines in southern Cologne, because it contained “an insufficient amount of iron oxide and alumina, so there was no risk that the phosphoric acid would become soluble” (Niederstadt, 1875).

According to Shepard, however, the principal problem for the development of phosphorite mining in Logrosán was, in addition to the transport costs (a problem common to the whole of the mining basin of Extremadura), “the tardiness of the Spanish courts when resolving the problem of the dispute” over the ownership of the Costanaza seam (Shepard, 1879: 27) and the possibilities of its rational mining. Boixereu (2003, 2004 and 2014) and Llanderas (2016) study the problem of the litigation in detail. The issue dated back to 1840, when Julián de Luna y de la Peña submitted an application to the town council of Logrosán to exploit the seam in common land. The exclusive right to exploitation was granted based on Article 2 of the Royal Decree of 4 July of 1825, which established that all types of siliceous stones and limestone soils required no concession by the mining sector.

The situation changed in the following years (1842 and 1844) when the General Directorate for Mining issued several orders in which phosphorite was included in Article 3 of the Royal Decree of 1825, establishing that all mineral substances were property of the State. This change was reinforced with the mining law of 11 April 1849 and the Royal Decree and regulations of 31 June of the same year.

Taking advantage of the new rules and at the request of the public attorney of Logrosán, the governor of Cáceres declared the authorisation given to Julián de Luna in 1845 as invalid. Ten years later (1855), on behalf of himself and other partners, Nicanor Fernández Bravo requested the governor of the province to authorise the exploitation of the phosphate of lime deposits in Logrosán. Three years later (1858), a Royal Order was published in the Gaceta de Madrid that authorised Pedro de Echevarría, the partner of Fernández Bravo, to verify, for a period of eight months, “the studies of a railway starting in Logrosán and terminating close to Cedillo (border with Portugal)”4. The idea of a railway line that would take the phosphate from Logrosán to Cedillo which would them be sent along the river Tajo from there to Lisbon, was considered again in 1859 by the French chemist Adolphe Bobierre (1859: 118-119), who consulted the unpublished study by his compatriot, the mining engineer Climent Rosway.

In the light of the legal actions against these and other resolutions proposed by Mario de Luna, son of Juan de Luna, the exploitation of the phosphorite in Logrosán slowed and a legal dispute began between the interested parties until a resolution published in the Gaceta de Madrid in February 1869 ruled in favour of Mario de Luna and cancelled the registers of Nicanor Fernández Bravo on the mines: Abandonada, Fundadora, Porvenir and Esperanza, granted by the governor of Cáceres in 1866, provided that Luna could accredit that he had fulfilled the mandatory “pueble” (obligation of keeping the mines active for a minimum of one year) prior to these dates (Boixereu, 2014: 8-9 and Llanderas, 2016: 33-41).

A year after the arrival of Shepard, Egozcue and Mallada believed that the problem surrounding the legal dispute of the ownership of Logrosán had excluded this deposit from the market at a time when the research conducted by the foreign companies and their agents in Spain on the phosphorite deposits was becoming more dynamic. A good example of this were the seams discovered in the area of Zarza la Mayor and Ceclavín (north-west of the province of Cáceres) in 1870. In an area of 29 kilometres, between this date and 1872, more than “twenty seams, which gave rise to the registration of almost one hundred mining registrations” were discovered (Egozcue and Mallada, 1876: 183-186 and 229).

One of these foreign companies was an British firm created for the exploitation of the deposits in the district of Alcántara (to which the municipalities of Ceclavín, Zarza la Mayor and Alcántara belonged), called “Estremadura Phosphate Company Limited” (hereafter, EPCL). With its headquarters in London, this company was established in July 1873 with the objective of purchasing and/or leasing “the mining, mineral and phosphate mine rights in the district of Alcántara”, as well as those of other minerals in Spain and Portugal and to construct all types of infrastructures related to this activity. This limited company was established with a social capital of 80,000 pounds sterling, divided into 2,000 shares at 20 pounds each and another 2,000 deferred shares at also 20 pounds each5. In December of this year, the company had 28 shareholders who owned 1,603 shares for a value of 32,060 pounds, which represented 40.7% of the issued capital. Five years later (1878), the number of shareholders had risen to 38 and the number of shares acquired to 3,603, representing 81% of the initial capital.

As we can observe in Table 1, the traders with their headquarters in London and Lisbon were the majority partners of the company with practically three of every four shares sold. They were those who directed the company. Next in importance came the landowners, mostly British landlords, who were more interested in the value of the mineral in the British market at that time than anything else. The rest were made up of civil engineers, insurers and lawyers with a percentage that represented 14.3% in 1873, falling to 10% in later years.

Table 1. Percentage of shareholders and shares in accordance with profession in the EPCL, 1873-1891

| |

1873 |

1888 |

1891 |

|||

|

Profession |

Shareholders |

Shares |

Shareholders |

Shares |

Shareholders |

Shares |

|

Trader |

60.7 |

50.0 |

66.7 |

71.1 |

66.7 |

71.7 |

|

Owner |

25.0 |

23.5 |

23.3 |

25.3 |

23.3 |

24.7 |

|

Lawyer |

3.6 |

3.1 |

0.0 |

0.0 |

0.0 |

0.0 |

|

Insurer |

3.6 |

1.6 |

3.3 |

0.6 |

3.3 |

0.6 |

|

Engineer |

3.6 |

6.2 |

6.7 |

3.0 |

6.7 |

3.0 |

|

Spinner |

3.6 |

15.6 |

0.0 |

0.0 |

0.0 |

0.0 |

|

Total |

100 |

100 |

100 |

100 |

100 |

100 |

Source: Own elaboration based on data drawn from The National Archives, Kew, London, Companies and Businesses Collection, BT 31/1708/6181. “Memorandum and Articles of Association of The Estremadura Phosphate Company Limited”.

We should highlight the role of the Shaw siblings (Rusell, James, Augus and Etheline), the first was a civil engineer, the two other brothers were traders and the sister had no profession. In 1878, the three brothers owned 67.8% of the shares. Ten years later (1888) and with the incorporation of Etheline as a shareholder, the family, from Birmingham, continued to constitute the majority shareholder with 55.5% of the shares. The brother with the most shares was, by far, James Shaw, who had 700 shares.

With respect to nationality, the British, and more specifically, the English, formed the absolute majority, representing 89.3% of the shareholders in 1873, followed by the Portuguese with 10.7%. In the last two years (1888 and 1891), the English representation fell to 66.7%, while that of the Portuguese increased to 26.7% (the trading brothers Pinto Basto and the Lisbon-born trader d’Oliveira Silva), with the remaining 6.7% of the shares in Spanish hands.

These Spaniards were Alfonso Rodríguez Aguirre, from Madrid, and Isidoro José Guerrero, from Alcántara. The former had 296 shares and the latter 389.

As well as the nineteen mines (Table 2), six purchased and the other thirteen leased, the companies also acquired land surrounding the bridge of Alcantará for the construction of a dock and also land related to some of the mines of Zarza la Mayor. The figurehead of the company in the town was Isidoro Cuerrero, who acquired the land for one of the Shaw brothers and for d’Oliveira Silva. The leasing contracts of the mines established the payment of a fee of 25 reales per tonne extracted (quality 65/70% BPL) to the owner of the land where they were located. This also occurred in the other phosphate mines of the province with the same quality (Dalençon, 1872: 80-82; Martínez and Boixereu, 2021: 4).

Table 2. Mines acquired and leased by the EPCL in 1873

|

Owned mines |

Town |

Leased mines |

Town |

|

Golondrina |

Aliseda |

Amistad |

Zarza la Mayor |

|

Fraternal / Agricultora |

Ceclavín |

Australia |

Aliseda |

|

Berenice |

Ceclavín |

Blanca |

Ceclavín |

|

Estrella |

Zarza la Mayor |

Ceclavinaria |

Zarza la Mayor |

|

Security |

Zarza la Mayor |

Consecuente |

Zarza la Mayor |

|

Dos Amigos |

Zarza la Mayor |

Diamante |

Cáceres |

|

— |

— |

Diana y Ceres |

Zarza la Mayor |

|

— |

— |

Esperanza |

Ceclavín |

|

— |

— |

Fortuna |

Ceclavín |

|

— |

— |

Maravilla |

Zarza la Mayor |

|

— |

— |

Paloma |

Zarza la Mayor |

|

— |

— |

Pastora and Requeja |

Zarza la Mayor |

|

— |

— |

Perla |

Zarza la Mayor |

Source: Own elaboration based on data drawn from The National Archives, Kew, London, Companies and Businesses Collection, BT 31/1708/6181. “Memorandum and Articles of Association of The Estremadura Phosphate Company Limited”.

On 1 September 1875, Segismundo Moret Prendergast, the former Minister of Finance in the first government of Amadeo I, ex-ambassador of Spain in London and who, one year later would play an important role in the development of the mining activity of Calerizo de Cáceres (Martínez and Boixereu, 2021: 4), signed a purchasing agreement with EPCL, whereby the British company acquired four of the mines leased three years earlier (Consecuente, Amistad, Maravilla and Fortuna) and also 36% of the Esperanza mine.

One of the main problems faced by the phosphate mining activity in Extremadura was the lack of a fast and efficient transport which increased the price of the product considerably in the markets of northern Europe. Contemporaries, such as the Frenchman Dalençon (1872: 87-106), “contractor of public works and mine exploitation in Cáceres”, or the engineers Egozcue and Mallada (1876: 186-187), had already contemplated the difficulties that this represented for the survival of the phosphate mining sector. Due to the lack of a railway line joining Cáceres with Portugal, the phosphate extracted from Alcántara was sent to Lisbon via the river Tajo. Before 1872, a French company had attempted to resolve the problem of descending the waters of the Tajo without investing in any infrastructures necessary to better navigate the river. To achieve its objectives, it used flat-bottomed boats with a height of 30 centimetres, a length of 18 to 20 metres and a width of 3.5 to 4 metres, similar to the model of the vessels used in France to descend the Loire and Allier rivers. The boats left Alcántara and when they reached Lisbon the goods were loaded onto an anchored sail or steamboat. After this operation, the boat was run aground and dismantled and the wood was subsequently sold.

Table 3. Calculation of the costs and earnings of a boat with 25 tonnes of phosphate, trip from Alcántara to Lisbon (rs/tonnes) (1872)

|

Concept |

Costs |

Concept |

Earnings |

|

Purchase of wood for a boat |

600 |

25 tonnes at 120 reales/tonne |

3,000 |

|

Sawing of the wood |

350 |

Sale of wood, assuming a loss of 50% |

300 |

|

Construction of the vessel |

600 |

Total |

3,300 |

|

Trip with 2 boatmen |

240 |

|

|

|

Return, cost and wages |

400 |

|

|

|

Subtotal |

2,190 |

|

|

|

15% management costs |

329 |

|

|

|

Total |

2,519 |

|

|

|

Sale |

3,300 |

|

|

|

Profits/Losses |

782 |

|

|

Source: Own elaboration based on data from Dalençon (1872: 97).

Although the data in Table 3 seem to indicate the feasibility of the Tajo as a means of transport, the circumstances soon revealed that it was not appropriate. Dalençon himself (1872: 95) indicated that it was necessary to channel the river between Alconetar and Alcántara, where “it narrows and produces a fast-moving current”, and between this town and Abrantes (Portugal), the point from which the Tajo is navigable. A few years later, Egozcue and Mallada (1876: 186-187) confirmed that “the great descent” of the flow of the river “caused by the long droughts in recent years, makes it impossible to navigate”, paralysing the shipments of phosphate mineral from the north-west of the province of Cáceres.

Another major problem of the deposits in the district of Alcántara was the reduction in the grade of the layers as they went deeper in the mines and the abundance of water at the lower levels. Between 1873 and 1875, the production of phosphate doubled from 2,500 to 5,087 tonnes. From this date, however, the situation changed. The reduction in the quantity of phosphate obtained and the transport problems were diverting the demand towards other deposits of the province, particularly those located a few kilometres from the capital. In 1881, only two of the nineteen mines of the district were in operation (Consecuente and Amistad). In the rest, the activity had been suspended6.

Although it is most likely that the economic activity of the EPCL ceased in the 1880s, the company did not legally disappear until 1892. The following year (18 April 1893), a new company was inscribed in the Joint Stock Companies register of London: the Estremadura Phosphate Syndicate Limited (hereafter, EPSL). With a social capital of 2,000 pounds, divided into 200 shares at 10 pounds each, this company was the result of an agreement between the official receiver of EPCL and the new company, chaired by the Irish engineer Frank Wynne. Made up of nine partners, including the also engineer James Shaw, the EPSL attempted to continue the objectives established by the EPCL in the preceding years. However it did not realise that, by then, and as we shall see in the following section, the phosphorite of Extremadura was no longer exported to the European market due to the competition of the phosphates from the Maghreb and the United States. In fact, the company was liquidated in 18967.

Another of the districts of the province where searches for phosphate were made was in the granite massif of Navalmoral de la Mata, to the north-east of the provincial capital. Investigations began in 1881 and the following year “some phosphate seams” were discovered8. For this reason, on 31 December 1882, the Sociedad Minero Industrial La Buena Estrella (hereafter, SMIBE) was established in Madrid. Its shareholders were: Francisco López Rubio, resident of Madrid and owner of the San Mateo mines in the municipal district of Navalmoral de la Mata, and San Esteban, San León and San Heriberto, in the Millanes, judicial district of Navalmoral de la Mata; Luis de la Torre Villanueva and León González de la Riva, both military men and residents in Madrid, and the trader from Cartagena, Heriberto M. Crea Carey. In accordance with the Banks and Deposit Companies Act of 1869, the SMIBE was formed to “explore and exploit mines in the judicial district of Navalmoral de la Mata and to develop all of the industries derived from the mining operations”. With an initial capital of 40,000 pesetas, divided into 80 shares of 500 pesetas each, Luis de la Torre and León García acquired 52.5% of them. Another 10% went to the hands of Francisco López, while the remaining 37.5% went to Heriberto M. Crea and Stephen Williams, in the concept of “business initiators” and the contribution of their scientific and trading knowledge. Similarly, it was agreed to issue 200 ordinary shares of 1,000 pesetas each, which would remain in the portfolio until the company, by a majority vote of two-thirds of its shareholders, considered it appropriate to put them into circulation. The SMIBE was presided for an unlimited duration by León González, its secretary was Heriberto Carey and the rest were board members9.

According to the scarce data that we have been able to obtain from the balance sheets of the company published in the Gaceta de Madrid in 1884, 1885 and 1887, the failure of SMIBE was immediate. With a core funding of 280,000 pts, which did not vary throughout the period, the costs of exploring the mines together with tangible costs amounted to 125,493 pts in the first year. Three years later (1887), and without any type of revenue, the costs doubled, accounting for 96.3% of own funds. The low quality and quantity of the phosphate mineral found accelerated the cessation of the economic activity, leading the managers of the company to put the mines up for sale in the early 1890s10. Due to the impossibility to sell them, the mines were leased for one year through an agreement signed on 22 September 1890 between the British engineer and contractor John Howell Stone (acting as the lessor) with permanent residence in London and residing temporarily in the Hotel Inglés of Madrid, with the also British Thomas Lund (acting as the lessee as the secretary of a company to be established), resident of London. In this agreement, the latter committed to acquiring “certain mining concessions for one year over an area of 4,500 acres in the judicial district of Navalmoral de la Mata”, with the option to purchase before the end of the first year. In this agreement, the company to be established was to pay 3,000 pounds sterling, payable in shares of one pound to the lessor, and a fee to the owners of the mines of 10, 7 and 5 shillings, respectively, for each tonne of phosphate extracted with a quality of 80%, 75% and 70% BPL. No fees would be paid for anything below these qualities. In the case where the company decided to purchase the mining rights, the lessor would receive the sum of 25,000 pounds.

On 26 September 1890, the limited company “The Phosphate Mines of Spain” (hereafter, PMOS), was registered in London with a nominal capital of 46,000 pounds sterling, divided into 46,000 shares at one pound each, 6,000 of which were reserved for the founding partners. The objective of the new company was, in addition to fulfilling the agreement, to purchase mines, mining rights or land rights in Spain and exercise these rights not only in the phosphate business but in that of any type of mineral11.

Table 4. Percentage of shareholders and shares by profession of the PMOS, 1890-1892.

| |

1890 |

1892 |

||

|

Profession |

Shareholders |

Shares |

Shareholders |

Shares |

|

Lawyers |

4.5 |

1.8 |

5.1 |

2.1 |

|

Administrators/Accountants |

5.5 |

2.9 |

5.1 |

2.7 |

|

Architect and Surgeons |

3.6 |

1.9 |

3.4 |

3.2 |

|

Traders |

7.3 |

31.1 |

7.7 |

17.3 |

|

Stockbrokers |

11.8 |

2.7 |

11.1 |

2.7 |

|

Manufacturers |

2.7 |

4.0 |

2.6 |

4.0 |

|

Spinners / Housekeeper |

6.4 |

2.2 |

6.0 |

2.2 |

|

Engineers |

4.5 |

6.2 |

4.3 |

6.2 |

|

Military men |

2.7 |

1.5 |

2.6 |

1.5 |

|

Married women and widows |

8.2 |

5.1 |

7.7 |

5.1 |

|

Shipping agents |

2.7 |

4.5 |

2.6 |

4.5 |

|

Nobleman, baron/ess, lord/lady |

2.7 |

3.8 |

2.6 |

3.8 |

|

Owners |

36.4 |

30.6 |

38.5 |

43.0 |

|

Clergymen |

0.9 |

1.8 |

0.9 |

1.8 |

|

Total |

100.0 |

100.0 |

100.0 |

100.0 |

Source: Own elaboration based on data drawn from The National Archives, Kew, London, Companies and Businesses Collection, BT 31/4882/32453. “Memorandum of Association of Lted the Phosphate Mines of Spain”.

In 1890, the number of founding shareholders amounted to one hundred and ten people who owned 5,615 shares. By profession (Table 4), two-thirds of the shares were owned by the traders and owners (61.7%), while the remaining shares were in the hands of a wide range of liberal professionals, businessmen and women, the latter grouped according to their civil status “married or widows” and/or their profession “spinners or housekeepers”. Together, the women accounted for 14% of the shareholders and 7.3% of the shares. When the company was liquidated (1892), the only noteworthy fact was that the traders had reduced their percentage of shares to almost half (17.3%), while the owners increased theirs to 43%. The failure of PMOS was a certainty even before it was founded, as it did not take into account the high opportunity cost of the investment in the poor and scarce seams discovered in the judicial district of Navalmoral de la Mata ten years earlier.

The last mining district where searches for phosphate were carried out was that located between the capital of Cáceres and the Montánchez mountain range (southernmost end of the province), particularly the deposits of Calerizo de Cáceres. The study of the companies that were established in this area has already been addressed by, among others O’Connor and Solano (2014) and Martínez and Boixereu (2021). Here, we will simply summarise the events occurring there in the time period.

Before the enactment of the progressive legislation of 1868 in mining, two companies were formed. The first, in 1864, was the Sociedad Especial Minera La Fraternidad (SEMLF). An example of the associative development of Spanish mining prior to 1868, this company was formed mainly by the owners of the lands where the deposits were located. Contrary to other companies operating in the area, the SEMLF directly exploited its deposits and sold its production to a Portuguese company. The second was the Spanish Mineral Phosphate Co. Ltd (SMPCL). Engaged in exploiting the phosphate deposits located in the Caleriz and the Montánchez mountain range, and with a capital of 100,000 pounds sterling, the company began operating in 1867. As we shall see in the following section, the instability caused by the third Carlist war led to a drop in phosphate production to 1,200 tonnes between 1873 and 1875, which brought about the bankruptcy of both companies in the second half of the 1870s. The next major player emerged in 1876 was the Sociedad General de Fosfatos de Cáceres (SGFC). The creation of this large company and the beginning of a new growth period in the production and export of phosphate mineral gave rise to a new golden period for mining in Calerizo de Cáceres, until the 1890s. From then, the high production costs, the low quality and international competition of other suppliers from the United States, Tunisia and Algeria, led to an economic and demographic crisis in phosphate mining of Extremadura from which it did not recover until the second decade of the twentieth century (Martínez and Boixereu, 2021: 4-6).

The boost from the technological transformation of British agriculture in the mid-nineteenth century, with the emergence of phosphate chemical fertilizer, increased the notoriety of the phosphate deposits in Extremadura. Hence, the search for maximising profits at the lowest possible cost attracted small and medium-sized British savers interested in obtaining shares of companies whose business strategies were not unlike that developed by their counterparts in other places in the peninsula.

3. The mining village of Aldea Moret

In 1872, only 39.4% of the phosphate mining labour force was located in the area of Calerizo de Cáceres, the place where the village of Aldea Moret emerged four years later. Apart from an insignificant 4.3% who lived in Montánchez, more than half of the miners (56.3%) were concentrated in the district of Zarza la Mayor – Ceclavín at the beginning of the 1870s, as this was the mining district where the first phosphates deposits began to be exploited (Egozcue and Mallada 1876: 187-240). The rapid exhaustion of the phosphate seams of this mining basin and the power of attraction resulting from the establishment of a large company such as SGFC close to the capital led to the displacement of the production centre of the phosphate mining sector of the north-west of the province to the area of Calerizo de Cáceres. The construction of the village of Aldea Moret by SGFC, with under adequate housing and health conditions, led to a concentration of workers in the area, which had begun in the previous years but had not developed until then.

Table 5. Number of inhabitants and miners in Aldea Moret, 1886-1925

|

Years |

Inhabitants |

Miners |

Percentage of Miners/Inhabitants |

|

1886 |

339 |

112 |

33.0 |

|

1898 |

213 |

45 |

21.1 |

|

1901 |

311 |

78 |

25.1 |

|

1915 |

755 |

193 |

25.6 |

|

1920 |

1,394 |

194 |

13.9 |

|

1925 |

846 |

237 |

28.0 |

Source: Own elaboration based on data of the municipal registers of Cáceres of those years.

In the municipal registers of Cáceres of 1886, 1901, 1915 and 1925, the number of miners, understood as those engaged in activities related to the extraction and classification of minerals, accounted for more than a quarter of the village’s population. The decrease in the population and the number of miners in 1898 was related to the drop in exports from 1895 and the closure and dissolution of SGFC. The figure of 1920 represented half of the mining population, as the other half was concentrated in trades related to the superphosphate factory in Aldea Moret which the Sociedad General de Industria y Comercio (GEINCO) established in 1907.

Aldea Moret acted as a catalyst in terms of attracting population, principally from the villages close to the capital with a certain mining tradition in the province. Between 1886 and 1901, an average of 57.5% of the people arriving in the village were from Cáceres. In the period between 1915 and 1925, this figure increased to 78%. On the contrary, the number of people from other nearby provinces, such as Castilla la Nueva and Castilla la Mancha was 12.2% for the years 1886 and 1901 and 7.8% between the years 1915 and 1925. This shows that the origin of the workers related to the labour activity in phosphate mining was fundamentally the province of Cáceres.

4. Production and consumption of phosphate, 1865-1956

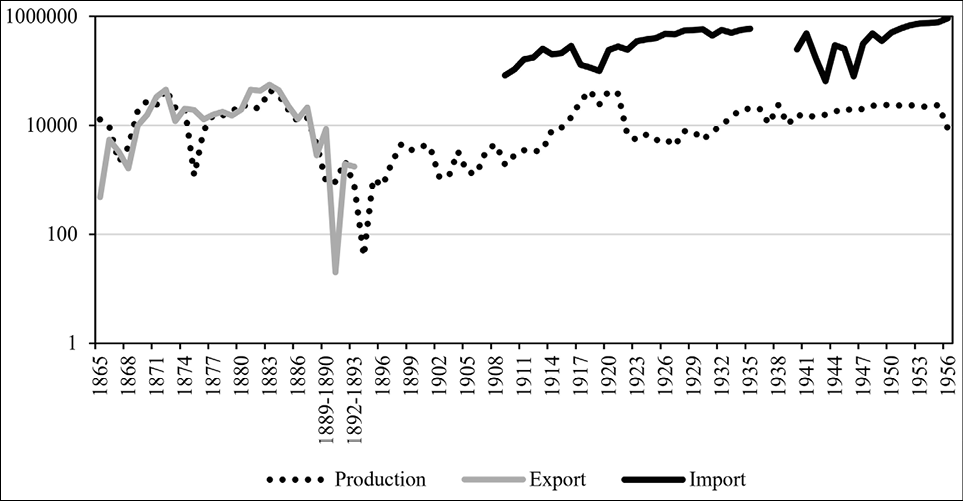

Between 1865 and 1956, the production of phosphate rock of Cáceres experienced two differentiated stages. The first, a purely exporting phase, coinciding with the boom in national mining12, began in 1868 and lasted until 1894, with a growth period between 1868 and 1872, followed by a decline and period of stagnation between 1873 and 1875, more prominent in production than in exports and which was, as previously explained, the consequence of the internal instability caused by the third Carlist war (Figure 1). After this sub-period, a new growth phase ensued between 1876 and 1883, in which the amounts exported in the years 1880 and 1881 exceeded more than double that of production, followed by a new and definitive decline in exports and production in the years between 1883 and 1894.

The export orientation of the phosphate production of Extremadura was the result of the low level of development of Spanish agriculture, which obliged phosphate to be exported to United Kingdom, Germany or France, through the port of Lisbon; the conditions of supply and demand explain its decline in the international market from 1893. From the demand side, phosphate arrived in Europe from the United States (first, South Carolina and then Florida) and the Maghreb (Tunisia and Algeria) of a higher quality and with lower production costs than Spanish phosphate. From the supply side, the gradual impoverishment of the phosphate mineral in some mines of Cáceres, the lack of demand of the mining activity in Logrosán due to the problems inherited from the legal dispute over the ownership of the mining rights and, most of all, the high price of transporting the mineral to Lisbon.

A good example of this is the fact that the share that phosphate from Extremadura had of global production fell from 7.3% in the period 1865-70 to 0.6% twenty years later (1886-1890).

The second stage began at the end of the nineteenth century and lasted until the closure of the mines of Cáceres in the mid-twentieth century. It was characterised by a production aimed at the domestic market with quantities that did not exceed ten thousand tonnes, except in some periods coinciding with the First World War, the years after the Great Depression and the autarchic period.

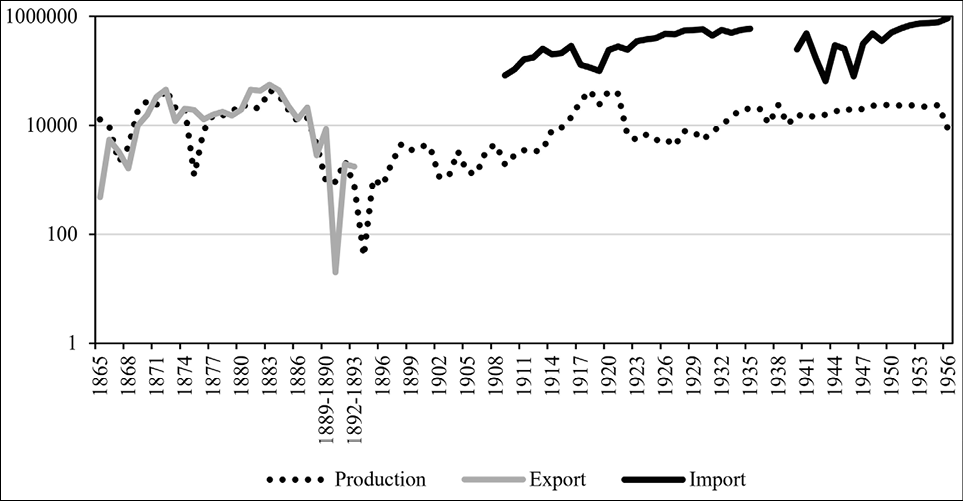

In the first two cases, the phosphorite from Extremadura was favoured due to the reduction in imports of phosphate from the Maghreb and the United States as a result of the increase in the price of maritime freights and the rise in the international value of phosphate (Figure 2), particularly during the Great War when the price doubled in real terms after having experienced a strong fall in the previous five-year period.

Furthermore, the growth experienced in the 1940s can be explained by an attempt to offset the fall in phosphate imports, due to the reduction in agricultural production and a moderate increase in international prices as a result of the world war, based on increasing costs which led to the closure of the Logrosán mines in 1943 due to the unproductive levels and those of Calerizo de Cáceres thirteen years later.

Paradoxically, the weight of imports, particularly those from the Maghreb13, of phosphate consumption in Spain was overwhelming in the twentieth century. Phosphate imports reached an average of 164,295 tonnes in the years 1909-1909. After a period of decline and stagnation between the beginning of the First World War and the early post-war years, the figures tripled between 1922 and 1935, reaching an average of 478,000 tonnes on the eve of the Civil War, thanks to the strong growth in Spanish production of single superphosphate. However, it was not until the 1950s when the growth in imports reached amounts close to a million tonnes, as a result of the concurrence of three factors: agricultural growth, an increase in the production of phosphate fertilizers and a greater international supply of natural phosphate at stable prices at around 40 dollars on average in constant terms (Martínez, 2017: 177-205).

5. Labour, market and integration in the phosphate mining industry of Extremadura, 1865-1956

In an article published in 1999 on the Andalusian lead mining company at the end of the nineteenth century, Pérez and Sánchez (1999: 292-293) warned that any “business analysis of the sector” had to be based on the acknowledgement of the duality existing between the extraction and elaboration. In the case of phosphate, and for the same period, this duality was more than evident, given the shortage of processing factories in the national territory, despite certain attempts to establish them.

After the loss of the European market at the end of the nineteenth century, the only possibility for phosphate from Extremadura was “the large-scale production of superphosphates and mineral fertilizers”14 in Spain. A first attempt was made in 1884. In this year, the SGFC and the Sociedad Española de la Dinamita (SED) founded La Cantábrica, Sociedad Anónima Española de Fosfatos Solubles, of which SED owned 65.5% of shares and the SGFC the remaining 34.6%. The factory was located in Galdacano (Vizcaya) in order to exploit the residual acids (specifically sulphuric acid) from the manufacture of nitro-glycerine. Meanwhile, the phosphate mineral was transported from the mines of the company to the port of Lisbon, from where it was shipped to Bilbao, and from there transported by rail to the factory. The results were not as expected. In 1887, the income statement of La Cantábrica reflected losses of 61,217 pesetas, which more than doubled three years later at 134,636 pesetas. As indicated by Gray (1945: 25), Nadal (1986), Gallego (1986), Pujol (1998) González García (2000: 59-61) and Boixereu (2014), the low level of demand for this type of fertilizer for the Spanish countryside and the rise in prices of the phosphorite from Extremadura due to the high transport costs put an end to this project. A second attempt was carried out at the beginning of the 1890s, when the SGFC opened a new superphosphate factory in Cáceres which closed after six months of operation15.

Therefore, it was not until the beginning of the twentieth century, when, attracted by the possibility of obtaining a cheap phosphate fertilizer, given the geographical proximity of Spain to the Maghreb phosphates, together with the possession of pyrite deposits, the base for sulphuric acid that the British, French and Spanish began to install phosphate manufacturing factories along the Mediterranean coast and in some inland areas (Nadal, 1986: 65).

In 1903, la Unión Española de Explosivos (UEE) constituted the Sociedad General de Industria y Comercio (GEINCO) in Bilbao with a social capital of twelve million pesetas. Geinco was created in order to produce single superphosphate and sulphuric acid. In the following year, factories were built in Vizcaya, Madrid, Cartagena, Malaga, Seville and Cáceres (Aldea Moret). In the case of Aldea Moret, Geinco acquired the factory that the Huelva-based company “Weteig, Weickert & Company” had previously established in the village. All of this is a clear example of vertical integration. According to the mining registry of 1909, Geinco, which had acquired the mines from the Cáceres-based company La Preferente a few years earlier, was the owner of 50% of the phosphorite concessions in Cáceres which represented 43.4% of the total area conceded16.

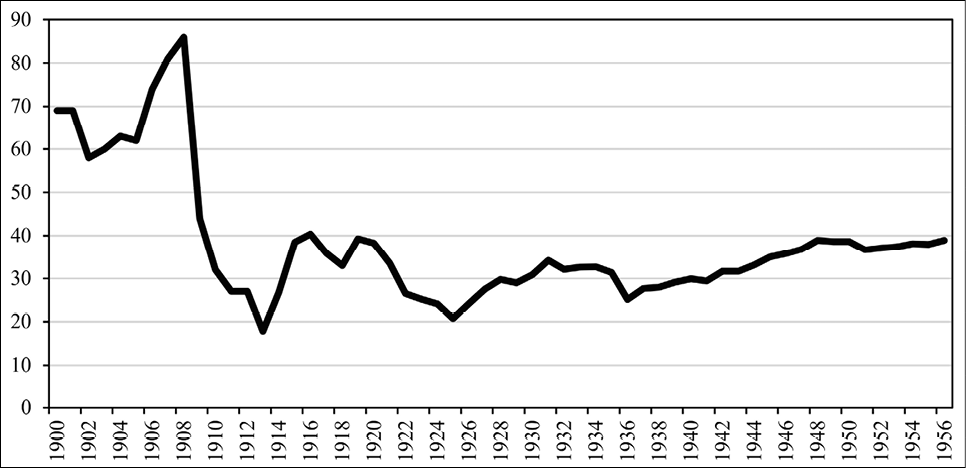

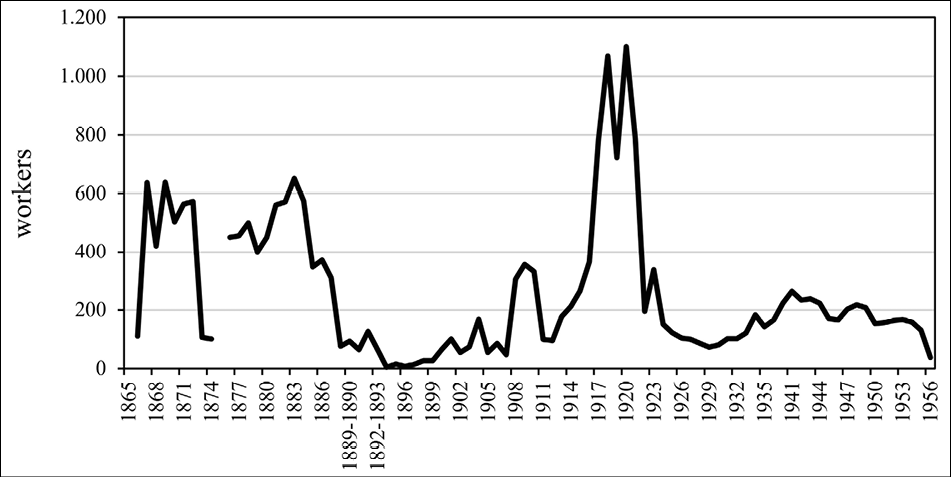

The operation of the phosphate mines (Figure 3) was intensive in terms of labour and in the use of energies and traditional techniques. After the end of the exporting phase, the employment figures fell and did not recover until the years of the First World War and the early post-war years, with peaks of over one thousand workers in 1918 and 1920. Between the mid-1920s and the mid-1950s, the labour force remained stable with no large variations. However, productivity, measured in tonnes per worker and year, tripled between 1925 and 1935, from 50 to 150 tonnes, thanks to the capital investments and a better organisation of labour. After the Civil War, productivity returned to 1925 levels, not reaching 150 tonnes again until the 1950s.

One of the specific characteristics of phosphate mining was the classification of the mineral in terms of quality after being deposited in the “sorting” locations. This activity was largely carried out by women and girls throughout the whole period of study. The exterior work carried out by the female workforce represented 18.2 of the labour used in the penultimate decade of the nineteenth century. This figure was not reached again until the first decades of the twentieth century and later fell by 0.4% between 1926 and 1935 (Martínez and Boixereu, 2021). At certain moments, such as in 1872 and 1909, in the latter case in five mines of Aldea Moret, women represented 30% of the labour force. It has been found that at the beginning of the 1870s, the female activity was not only concentrated in the selection and classification of the mineral but also represented a substantial percentage (14.6%) of the “zafreros” who transported the mineral from the mine entrance to the points of classification. All of this at a nominal wage per hour worked which, in 1920, was half that of their mining colleagues.

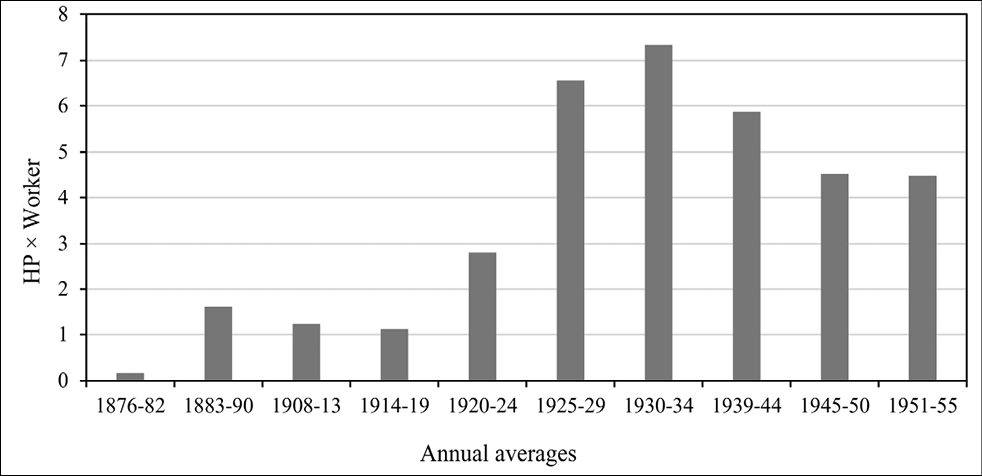

The mechanisation, measured in horsepower (HP) per worker, was a slow process which only gained momentum in the 1920s and beginning of the 1930s and later stagnated in the final decade of phosphate mining in Extremadura (Figure 4). Of the two mining centres (Aldea Moret and Logrosán), Aldea Moret was the first to begin the modernisation of its mining installations. By 1914, the dewatering pumps had already been installed, together with the telephone communication with the outside and kiln cars. With respect to the energy used, a 150 HP electricity generating plant had begun operating while another with the same power was under construction. The same was not the case in Logrosán, where, in 1916, the horse-powered winch system was still being used to extract the water from the bottom of the mine17.

In the mine of Aldea Moret, four different qualities of phosphate were produced: 40-45% BPL, 45-50% BPL, 50-55% BPL and 55-60% BPL. The first two were obtained in the superphosphate factory of the town and certain quantities were also sent to Salamanca and factories in Portugal, while the latter two were sent to those that GEINCO owned in Madrid and Seville18. Contrary to what was done in the rest of the mining basin, Aldea Moret did not wash the phosphate before the “sorting” process, as the gangue could be distinguished from the mineral. After the crushing process, the phosphorite was classified in terms of its quality and its size: “Grueso” (coarse) (15-20 cm) and “menudo” (fine) (2.5 cm). The manufacture of the “almendrilla” size (small almond), which was smaller in size than the “menudo” had been discontinued some time before.

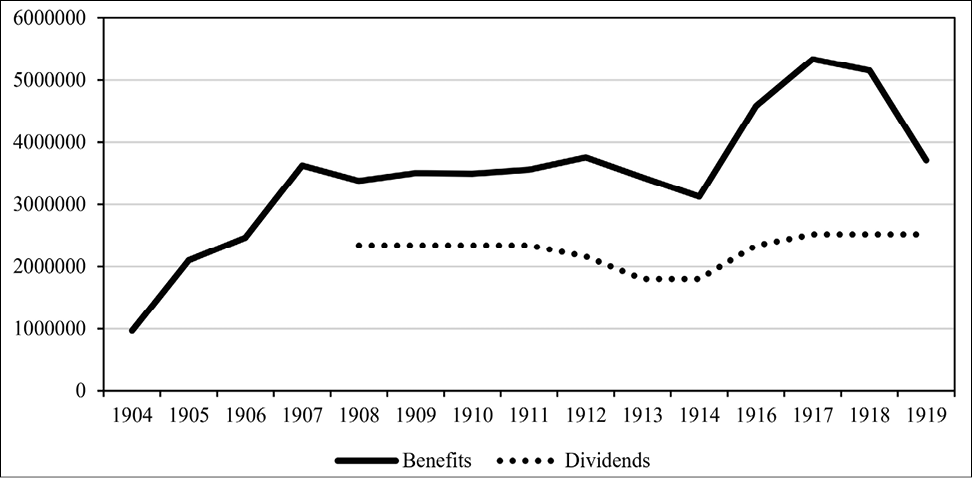

As we can observe in Figure 5, the profits of GEINCO almost quadrupled between 1904 and 1907, remaining stagnant, together with the dividends, between this latter year and 1912, falling again in the two years prior to the First World War. After the strong growth in profits between 1914 and 1918, due to the closure of the European markets and the increase in the freight rates, they fell again in the space of one year (1919) to the level of 1912.

The causes can be found in the strong competition existing in the domestic phosphate fertilizer market and in the increase in Spanish imports of phosphate from the Maghreb and the USA in the inter-war period, favoured by a fall in the international price of the mineral between 1919 and 1925 from 41 to 21 dollars, decreasing to pre-war levels. This fact, together with the reduction in the quality of the phosphate from Extremadura, caused the superphosphate produced in Aldea Moret to fall from 16,000 tonnes in 1921 to 3,000 tonnes in 1922.

In 1920, GEINCO was taken over by the Unión Española de Explosivos (UEE) which continued exploiting the mines and manufacturing superphosphate for those interior markets close to the production points. In fact, the reduction in the quality of the mineral as the extraction activity deepened in the deposits obliged the company to increase phosphate imports from the Maghreb to mix with the poorer phosphate from Extremadura and obtain a single superphosphate that was able to compete. In 1922, thirteen% of imported phosphate rock was used. A year later, the amount used had almost doubled (22%).

Until the beginning of the 1930s, phosphate production in Aldea Moret did not exceed the average of 4,000 tonnes of the 1920s, due to the worker’s strike at the end of 1918 and the paralysis of the mining activity in the following year resulting from the company’s refusal to meet the demands of the workers with respect to working conditions (Martínez and Boixereu, 2021). This led to an increase in the stock of poor minerals which were consumed in successive campaigns19.

In order to obtain the richest concentrate possible of the poor phosphate to reduce the dependence on imports and achieve a superphosphate with a high content of phosphoric acid, the UEE installed a flotation washer20 in the beneficiation plant with two workshops: the primary crushing workshop and the grinding and washing workshop. The results obtained were limited as the amount of imported phosphate was not reduced. In 1939, after the Civil War, the superphosphate factory was able to enrich the 35% BPL phosphate to 52% BPL, which was directly used for producing superphosphates with a richness of 13/15, the lowest grade of all the soluble fertilizers manufactured21.

The evolution of La Constanza mine in Logrosán was not very different. After a long legal dispute over the ownership of the mining rights in the last quarter of the nineteenth century, the new owners, Piper and Boudriot, based in Lisbon, resumed the operations inside the mines in 1907. In the mining registry of 1909, the new owners possessed 12.99% of the phosphorite concessions in Cáceres, which represented 10.58% of the total area conceded. Five years later (1912), the concessions were granted to the trading house Harold Hermanos of Lisbon (Jerosch, 2016: 5-6), which renewed for a further ten years the contract which the previous owners had with the superphosphate factory of the Hermanos Mirat in Salamanca, to supply 8,000 annual tonnes of phosphate rock.

The quality of the phosphorite of Logrosán was superior to that of the rest of the mining district (48-70% BPL) and, unlike Aldea Moret, the mineral was classified into four different sizes: “Grueso” (coarse) (larger than 4 cm), “almendrilla gruesa” (coarse almond) (2.5-4 cm), “almendrilla menuda” (fine almond) (1.2-2.5 cm) and “menudo” (fine) (smaller than 1.2 cm). The mineral classified as “almendrilla” was washed when it left the mine, separating the good phosphate from the quartz phosphate22.

The extraction conditions improved substantially from 1917 with the installation of dewatering pumps and an electrical generator driven by two gas motors of 55 HP each, which powered five or six hammer drills. Three years later (1921) three motors with a total power of 400 HP were operating, together with six compressors which powered 40 or 50 hammers “for drilling galleries and extracting the mineral”23. However, the lack of a rapid and efficient transport continued to make the price of a tonne of phosphate 60% more expensive. Until 1916, the mineral was transported in carts by road from Logrosán to Cáceres. One year later, the carts were replaced with five lorries with a capacity of five tonnes each, purchased by Mirat Hermanos.

In May 1922, the Sociedad de Fosfatos de Logrosán (SFL) was constituted before the notary of San Sebastián, Luis Barruete. The first chairperson of the board of directors was the Salamanca-born agricultural engineer Gregorio Mirat. The following year (1923), the SFL acquired the mining concessions of Logrosán. In order to generate economies of scale, a sulphuric acid factory was built in the town (which burned down in 1928), to complement the superphosphate factory that it had in Villanueva de la Serena (Badajoz). However, the transport cost continued to represent a problem for the company. In the case of the journey between Logrosán and Salamanca, the transport costs represented 63.2% of the final price per tonne24.

Although phosphate production between 1917 and 1930 was higher than that of Aldea Moret by more than 50,000 tonnes, the lack of a railway line that connected the mine with Cáceres capital or Talavera and the progressive exhaustion of the deposits led to its closure in 1943.

Although the extraction of phosphate in Cáceres was discontinued in the mid-1950s, the superphosphate factories of Aldea Moret and Villanueva de la Serena remained active until at least the mid-1960s, with a production, in 1964, of 100,000 tonnes of single superphosphate in Aldea Moret and 70,000 tonnes in Villanueva de la Serena25.

The discontinuation of the economic activity in the phosphate mines of Extremadura was the result of the scarce reserves, the low grade (lower than 40% BPL), the hardness of the gangue and the costly enrichment treatment of the mineral which placed it “on an inferior level” compared to the African phosphates26.

6. Conclusions

The boom in phosphate mining in Extremadura in the last third of the nineteenth century was possible thanks to agricultural demand in north-west Europe, closely related to the emergence of the first phosphate chemical fertilizer. All of this led to a voracity of land reconnaissance operations in different parts of Cáceres by British, Spanish and to a lesser extent, French mining companies. The seven companies created were established in three places: the district of Alcántara, the massif of Navalmoral de la Mata and Calerizo de Cáceres. Given the scarce reserves and the decrease in the grade of the mineral at some times or the transport problem at others, Calerizo de Cáceres concentrated the majority of the extraction operations and export of Extremadura phosphate to markets in northern Europe, through the port of Lisbon.

In addition to the problem of the quality of the mineral and its deterioration the deeper it was extracted from the mine, the principal handicap of phosphate mining in Extremadura was the lack of a transport that would reduce the impact of its cost on the final price of the phosphate, despite the establishment of a railway line joining Madrid with Lisbon through Cáceres. The start of production of new mines in the United States and Africa, together with the fall in freight rates to Europe at the end of the nineteenth century, brought the above-mentioned problems to light. The enormous reserves and the higher quality of North American and African phosphate displaced the phosphorite from Extremadura to the domestic market.

Throughout the first third of the twentieth century, superphosphate factories were built across the peninsula in response to the development of Spanish agriculture. However, the gradual reduction in the quality of the phosphate reserves of Extremadura meant that Spanish phosphate lost profitability compared to its foreign competitors in the domestic market.

Even though the working conditions, organisation and productivity in Aldea Moret and Logrosán improved as the century progressed, the afore-mentioned problems and the expensive process of enriching the phosphate mineral to obtain a competitive soluble fertilizer gave rise to the closure of both mining centres during the first phase of the Franco regime.

Bibliography

BOBIERRE, Adolphe (1859): Études chimiques sur le phosphate de chaux et son emploi en agriculture. Paris: Librairie Agricole.

BOIXEREU, Ester (2003): “Historia y Patrimonio Minero de Logrosán (Cáceres). La mina de fosforita Costanaza”, in Patrimonio geológico y minero y desarrollo regional. Publicaciones del Instituto Geológico. Cuadernos del Museo Geominero, 2: 169-176.

BOIXEREU, Ester (2004): “Mina de fosfato La Costanaza, Logrosán, Cáceres”, Tierra y Tecnología, 26: 25-34.

BOIXEREU, Ester (2014): “El yacimiento de fosfato de Logrosán (Cáceres, España), in Mito, Ciencia y Progreso. Actas del XV Congreso Internacional sobre patrimonio geológico y minero. XIX sesión científica de la SEDPGYM. Logrosán.

BOWLES, Guillermo (1789): Introducción a la Historia Natural y a la Geografía física de España. Madrid, Imprenta Real (3ª edición).

CHASTAGNARET, Gérard (2000): L’Espagne, puissance minière dans l’Europe du XIXème siècle, Madrid : Casa de Velázquez.

DALENÇON, E. (1872): Estudio sobre las minas de fosfato de cal del Distrito de Cáceres. Cáceres, Imprenta de Fernández y Cia.

DECKERS, A. (1894): Étude complète sur les phosphates. Liège, Imprimerie Liégeoise, H. Poncelet éditeur.

DOUGUI, N. (1995): Histoire d’une grande entreprise coloniale : La compagnie des phosphates et du chemin de fer de Gafsa, 1897-1930. Tunis, Publications de la Faculté des Lettres de la Manouba.

EGOZCUE, J. & MALLADA, D.L. (ingenieros de minas) (1876): Memorias de la Comisión del Mapa Geológico de España. Memoria Geológico-Minera de la Provincia de Cáceres. Madrid, Imprenta y Fundición de Manuel Tello.

ENMINSA (1965): Industria de fertilizantes fosfatados en España. Madrid, Kabana.

ESCUDERO, Antonio & PÉREZ DE PERCEVAL VERDE, Miguel Á. (1994): “Treinta años de estudio sobre minería”, Áreas. Revista Internacional de Ciencias Sociales, 16: 11-31.

GALLEGO MARTÍNEZ, Domingo (1986): “Transformaciones técnicas de la agricultura española en el primer tercio del siglo XX”, in Ramón Garrabou, Carlos Barciela & José I. Jiménez Blanco (eds.), Historia agraria de la España Contemporánea (1900-1960). Barcelona, Crítica, vol. 3: 171-229.

GÓMEZ AMELIA, D. (1978): Aldea Moret. De poblado minero a suburbio cacereño. Cáceres, Aula de Cultura de la Caja de Ahorros y Monte de Piedad de Cáceres.

GONZÁLEZ GARCÍA, J.M. (2000): La industria de explosivos en España: UEE (1896-1936), Madrid, Fundación Empresa Pública, documentos de trabajo.

GRAY, A.N. (1943): Phosphates and Superphosphate. New York, Interscience Publishers Inc.

IGME (1962): “Estudio de los criaderos de fosfatos de la parte centro-oriental de la provincia de Cáceres”, in Notas y Comunicaciones. Instituto Geológico y Minero de España, 66: 267-290.

JEROSCH HEROLD, B. (2016): “Empresàrios e técnicos alemães residentes em Lisboa e a Grande Guerra de 1914-1918”, Academia das Ciências de Lisboa: 1-17.

LLANDERAS LÓPEZ, A. de las (2016): “El litigio de la fosforita de Logrosán y la aplicación de la legislación minera en el siglo XIX”, Boletín de la Real Sociedad Española de Historia Natural, Sección Geología, 110: 29-41.

LÓPEZ MORELL, Miguel Ángel & PÉREZ DE PERCEVAL VERDE, Miguel Á. (2019): “From old mining to new mining: the introduction of differential flotation in Spanish mines and its environmental impact”, Revista de Historia Industrial, 77: 119-148.

MARTÍNEZ MILÁN, Jesús María (2017): “La larga puesta en escena de los fosfatos del Sahara Occidental, 1947-1969”, Revista de Historia Industrial, 69: 177-205.

MARTÍNEZ MILÁN, Jesús María & BOIXEREU VILA, Ester (2021): “Aldea Moret: un núcleo obrero cacereño ligado a la minería del fosfato, 1865-1925”, Investigaciones de Historia Económica, 18 829, 102-112. https://doi.org/10.33231/j.ihe.2021.04.014

NADAL OLLER, Jordi (1975): El fracaso de la Revolución Industrial en España, 1814-1913. Barcelona, Ariel.

NADAL OLLER, Jordi (1986): “La debilidad de la industria química española en el siglo XIX”, Moneda y Crédito, 176: 33-70.

NADAL OLLER, Jordi; Escudero, Antonio & Sánchez Picón, Andrés (2003): “Orto y ocaso de una potencia minera”, in Jordi Nadal Oller (dir.), Atlas de la industrialización de España, 1750-2000. Crítica/Fundación BBVA, Barcelona: 101-133.

NIEDERSTADT, B.C. (1875): “Estremadura Phosphorite”, The Chemical News and Journal of Physical Science, vol. XXXI: 144.

O’SHEA, G. (1922): “Estudio del criadero de fosforita de Logrosán (Cáceres)”, Boletín Oficial de Minas y Metalurgia, 60: 1-11.

O’CONNOR, B. & SOLANO, L. (2014): The Spanish Phosphateers: the origins and development of Spain’s phosphate industry. S.l., s.n., fquirk202@aol.com.

PÉREZ DE PERCEVAL VERDE, Miguel A. & SÁNCHEZ PICÓN, Andrés (1999): El plomo en la minería española del siglo XIX. Evolución del sector y panorama empresarial. Madrid, Fundación Empresa Pública, documento de trabajo.

PROUST, L. (1791): Sobre la piedra fosfórica de Extremadura, Anales del Real Laboratorio de Química de Segovia, 1: 439-450 and 453-456.

PUJOL ANDREU, J. (1998): “La difusión de los abonos minerales y químicos hasta 1936: El caso español en el contexto europeo”, Historia Agraria. 15: 143-182.

ROSO DE LUNA, M. (2007): Logrosán. Legajo histórico. Cáceres, Ayuntamiento de Logrosán.

SÁNCHEZ RODRÍGUEZ, Alejandro (dir.) (2009): Estudio del patrimonio minero de Extremadura. Madrid, Instituto Geológico y Minero de España/Junta de Extremadura.

SÁNCHEZ RODRÍGUEZ, Alejandro & MARCHÁN SAUZA, Carmen (2014): Aproximación a las líneas generales de la evolución de la minería española contemporánea. Comunicación presentada al XI Congreso Internacional de la AEHE, CUNEF, Madrid.

SÁNCHEZ PICÓN, Andrés (2018): “Expansión minera y reforma liberal. Peculiaridades de un cambio institucional en la España del siglo XIX”, Áreas. Revista Internacional de Ciencias Sociales, 37: 144-157.

SHEPARD, Charles U. (1879): Foreign phosphate, being a lecture delivered before the Young Men’s Christian Association, The News and Courier Book Presses, Charleston.

ZENAIDI KARRAY, B. (1987): Le marché mondial des phosphates et des engrais phosphatés. Paris: Economica (2ª ed.).

1 This study has been financed by the Spanish Ministry of Science, Innovation and Universities through the Project PGC2018-097817-B-C31. I would like to express my gratitude to Miguel Ángel Pérez de Perceval Verde for his kindness in providing me with the information regarding the documentation of the British companies stored in the National Archive in Kew, London.

2 Single superphosphate is obtained by adding sulphuric acid to the phosphate mineral.

3 The richness of the phosphate mineral is measured by its content in phosphorous, which is expressed in tricalcium phosphate (TPL), also known as BPL (Bone Phosphate of Lime). The mineral was sold according to its percentages of BPL, which fluctuated between 55% and 85%.

4 Gaceta de Madrid, 26 June 1929, nº 205, 1.

5 The National Archives, Kew, London, Companies and Businesses Collection, BT 31/1708/6181. “Memorandum and Articles of Association of The Estremadura Phosphate Company Limited”.

6 Estadística Minera y Metalúrgica de España (hereafter, EMME) (1881: 72)

7 The National Archives, Kew, London, Companies and Businesses Collection, BT 31/5566/38726. “Memorandum and Articles of Association of The Estremadura Phosphate Syndicate Limited.” And O’Connor and Solano (2014: 105-111).

8 EMME, 1885: 83-84.

9 Gaceta de Madrid, n.º 365, 31 December 1882: 825-826.

10 Gaceta de Madrid, n.º 41, 10 February 1885: 425. Gaceta de Madrid, n.º 41, 10 February 1886: 411. And, Gaceta de Madrid , 18 May 1887, 138: 432.

11 The National Archives, Kew, London, Companies and Businesses Collection, BT 31/4882/32453. “Memorandum of Association of Lted the Phosphate Mines of Spain”.

12 On the boom in national mining in the second half of the nineteenth century, see, among others, Nadal (1975, 1981), Chastagnaret (2000), Nadal, Escudero & Sánchez Picón (2003), Pérez de Perceval & Lopez-Morell (2006) and Sánchez & Marchan (2014).

13 The data on the international prices of phosphate provided by the U.S Geological Survey for the twentieth century, do not disaggregate the price of the mineral in terms of quality. According to authors such as Gray (1945) and Dougui (1995), in the 1920s there was a mismatch between the price of the lower quality phosphate from Tunisia and Algeria (58/63% BPL) and the price of the richest phosphate mineral (75/77% BPL) from Morocco. There are two reasons that explain this: the Moroccan mineral was easier to extract than the Maghreb phosphates and it was richer in phosphoric acid and less dependent on sulphuric acid, making it ideal to obtain superphosphates of 18%.

14 EMME (1885: 138).

15 EMME (1889-1890: 347).

16 EMME (1909: 168-170).

17 EMME (1914: 133-154) and (1916: 136-137).

18 EMME (1907: 136) and (1916: 133-134).

19 EMME (1922: 150), EMME (1923: 163) and EMME (1930: 214).

20 The general principle of flotation consists in mixing in a tank of water phosphate rock and reactive chemicals. Thanks to these chemicals, which in the case of Aldea Moret were soap and pine oil, the phosphate particles adhered to the air bubbles and formed a foam on the surface of the tank, while the impurities and sterile substances were extracted from the bottom of the tank. EMME (1935: 247-251), Zenaidi (1987: 23) and López and Pérez (2019).

21 EMM (1939: 265).

22 EMME (1916: 139).

23 O’Shea (1922: 1-11).

24 EMME (1919), EMME (1922: 148) and EMME (1933: 315).

25 ENMINSA (1965: 32).

26 IGME (1962: 268 and 287-288).

Figure 1. Apparent consumption of phosphate in Spain 1865-1956 (tonnes) (semilogarithmic scale)

Source:

Own elaboration with data from EMME, Estadística del Comercio Exterior

de España, Gray (1943: 264-265) and Nadal (1986)

Figure 2. International prices of phosphate mineral 1900-1956 (1998 dollars)

Figure 3. Number of workers in the phosphate mining industry, 1865-1955

Source: Own elaboration based on data from EMME.

Figure 4. Mechanisation of phosphate mining (HP per worker), 1876-1955

Source: Own elaboration based on data from EMME.

Figure 5. Profits and Dividends of GEINCO

(1904-1919) (pesetas)

Source: Own elaboration based on data from González (2000).